Our Product List

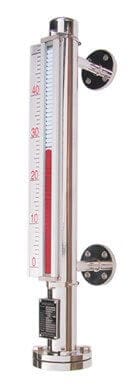

Magnetic LEVEL INDICATOR

[SERIES : MFMLI]

Installation Specifications

| Installation | Side/Top |

| CC-Distance | 300 mm to 5000 mm |

| Chamber | ǿ60.3 mm in SS304/SS316/SS316L/PP |

| Vent/Drain | ½” threaded |

| Process Connection | For Side mounting: 25NB/40NB/50NB flanges to 100NB flange to BS/ANSI/DIN or ½”/¾”/1” BSP/NPT (M/F) Threaded For Top mounting: 100NB flange to BS/ANSI/DIN |

| Level Display | Bi-color magnetic flappers SS304/SS316 |

| Float Mounted | For Side mounting: ǿ50 mm in SS304/SS316/SS316L/PP For Top mounting: ǿ75 mm in SS304/SS316/SS316L/PP |

| Scale | SS304 |

| Max. Temp. | 70°C (PP), 400°C (SS) |

| Pressure | Up to 50 kg/cm² (SS), Up to 2 kg/cm² (PP) |

| Min. SG | 0.6 |

DESCRIPTION:

The MICRO FLOW magnetic level indicator bi performance Instruments for Level Indication. It is a single chamber design with 2″ Chamber diameter, as required by the application. There are different Configuration styles, including top mounted models. Magnetic level indicators are produced in a wide range of materials of construction, Including plastics. We also offer one of the mos Process connection types and sizes as per various standards of the industry.

These Level Indicators may be equipped with a variety of level transmitters and switches, as well as, flapper indicators with or without stainless Steel scales. Application are high temperature, high pressure, strong acids, Alkalis & hazard locations, boiler power generation, petro chemical etc.

OPERATION:

A float of compatible MOC, carrying a magnet, is immersed in the liquid and moves due to buoyancy. The movement is conditioned within an SS Float Chamber. External to the Float Chamber is a Glass Tube carrying a Magnetic Follower and an Indicating Assembly consisting of Magnetic strips. The magnet on the Float and the magnet on the Magnetic Followers are coupled to move in unison. When the Float moves along with the change in liquid level, the Magnetic Follower moves in unison inside the Glass Tube and SS magnetic strips, thereby allowing clear visibility of the level.